Special Service Care

Our manufacturing industry is the best manufacturing industry which excites best service of Heat Exchanger Manufacturers . It often ensures good quality of service with hi-tech innovative technologies.

Most Latest Product Store

Heat Exchanger Manufacturers provide latest store products at affordable cost price with unique specifications which satisfies the demands with good mitigations. In order to View our Products to know more.

Exclusive Support Team

Our team of manufacturers gives good support with exclusive service thus to provide high-standardized custom products which imparts the best support in delivering the finite terms of service

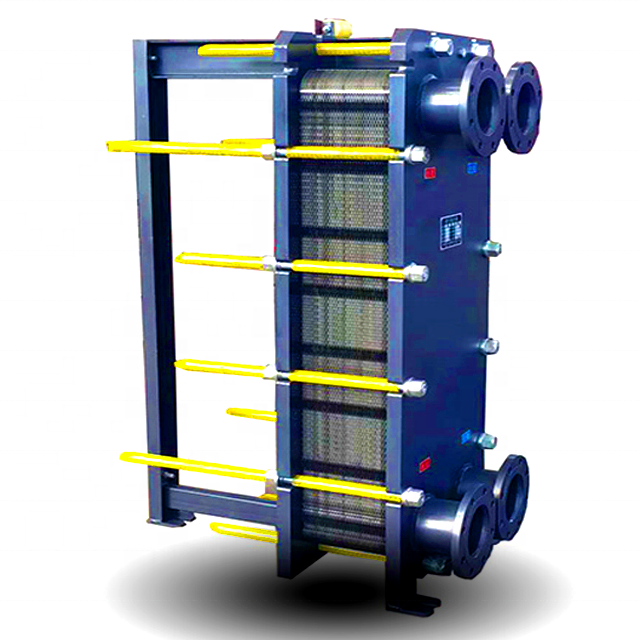

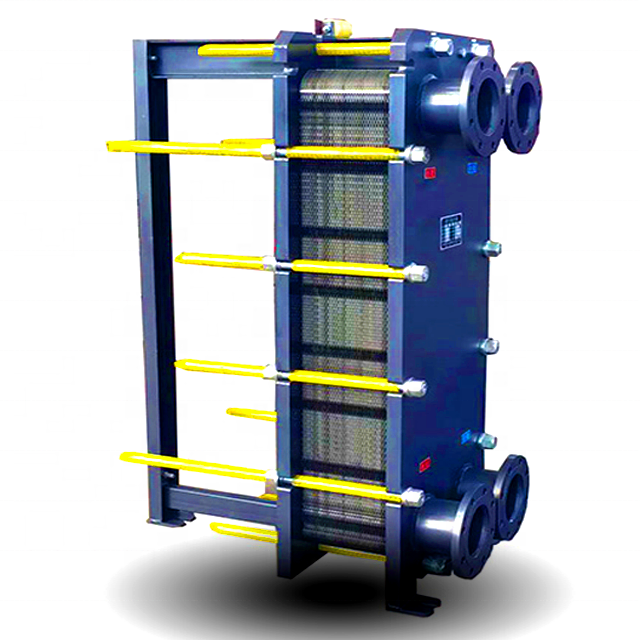

Heat Exchanger Manufacturers 01

Welcome to Pioneer Engineering Works

‘Pioneer engineering works’, we are the top rated and ISO 9001:2005 certified industrial equipments heat exchanger manufacturers and service provider in Coimbatore. With the market understanding and industrial experience of more than 7 years, we manufacture and offer the quality approved industrial equipments such as Shell and tube heat exchanger, Shell and tube oil cooler, Hydraulic Oil Cooler, Air cooled heat exchanger, Air blast oil cooler, Shell and tube condenser, Shell and tube evaporator, Air pre heaters, Steam Radiator, Steam heat exchanger, Turbine oil Cooler, Alternator cooler, Marine charge Air cooler , Fin fan cooler , Generator heat exchanger, Mining oil cooler, Tea dryer radiator , Garment dryer radiator, Thermic fluid radiator, Dry Cooling Towers and much more to various industrial applications. We are servicing all over the India, there are no boundary limits for our services. Being the global leader in the industrial equipment and cooling solution industry, we work with the quality assured material and sophisticated technology for manufacturing the precise heat exchangers and oil coolers. Our vital goal is to offer the best possible machine cooling solutions within the specified time scale. Backed by the team of highly experienced professionals, hi-tech machinery and modern manufacturing unit, we offer innovative and energy efficient machine cooling solutions at an affordable price in the market. Additionally, in order to ensure the best client experience and fulfill their needs and requirements, we offer tailor-made machine cooling solutions with different capacity, shapes and sizes.

Learn MoreOur Products

Shell and Tube Heat Exchangers

Shell and Tube Oil coolers

Hydraulic Oil Coolers

Air Cooled Heat Exchangers

Air Blast Oil Coolers

Shell and Tube Condensers

Shell and Tube Evaporators

Air Pre Heaters

Steam Radiators

Steam Heat Exchangers

Turbine Oil Coolers

Alternator Coolers

Marine Charge Air Coolers

Fin Fan Coolers

Generator Heat Exchangers

Mining Oil Coolers

Tea Dryer Radiator

Garment Dryer Radiator

What People’s Say About Our

Company Products20

Our Testimonials

Pioneer engineering works, best heat exchanger manufacturers in coimbatore. Thanks for providing high quality products

Thanks for providing high quality products for market leading price.

Thank you for Pioneer Exchanger to offer good service and support in delivering the products.

It is really good in power consumption and having low cost of estimations with less maintenance service.

Who We Are

Heat Exchanger Manufacturers is a prominent industry in manufacturing, supplying and delivering the products with best service support. Our industry establishes excellent service in rendering high-quality of products with approval. It might works well for longer durability of life as well as with good reliability, tensile strength, and versatile in nature of the products. It provides a fully-fledged customer support and delivery to ensure the best service with premium quality machine as in catering the needs and demands of our reputed customers.

Satisfied Clients

Number of Products

Our Employees

orders completed

Our Team of Expert Manufacturers optimize in designing innovative and efficient heat exchanger and other related products. This product manufacturer performs high-optimized support in bringing up the customized and highly proficient team of servicing the finite aspects of manufacturing products at low cost of minimum budget price in the leading market. People choose our industry to have their products with full-integrated system of focusing good and service products ever.

Frequently Asked Questions

Heat exchanger manufacturers transfer the fluids from one gaseous substance to other substances. The majority of the heat energy is made by an engine and they need to be freed from the surroundings by some heat exchangers. The heat exchanging manufacture is used in refining the cracking unit process of the natural liquefying gas. It is more simple to process and has the efficiency and speed that depends greatly on the size of the surface partition and is used in both cooling and in the heating process.

The structure of heat exchange manufacture varies due to many terms such as plate and tubular walls. These manufacturers have plates and walls that are commonly made from stainless steel and it acts as a conductor with high durability. The two plates' substances separate and endure high pressures and with extreme temperature. The equilibrium and a thermal stress are created inside the wall or in the tube temporarily. This Heat exchange transfers the heat part to the cooler part. This is how the heat exchanger manufacture works and happens when the heat exchange is in process to have a cool part.

Yes, it is frankly need to elaborate that our expert manufactures perform their best in manufacturing the products with full safe and comfort. The process of manufacturing the heat exchanger step out the comprising flattening of opposite sides which aids high performance in giving finite positioning with good quality. Thus to know more about the manufacturing process of heat exchangers, visit our industry and grow up your business with best service and support.

The cost of Heat Exchanger products are determined as per the depending upon the size of furnace and the brand. Though, to describe it more elaborately, you need to look at our products service widely which will demonstrate you the best service and can be determined the price rate. In short, it is often purchased in low cost of minimum budget price.

Heat exchanger and other related products are expensive in replacing the parts of the products extensively. Unfortunately, it can take 10 to 15 hours for a tech to replace it.

Magnetic Tube Materials are well treated by eddy current in the usage of saturation techniques. Examining the technique of products is normally carried in depending upon the condition of work. It is widely tested many times with high concentration and is possible in examining good products at less minimum budget price which inspects possible aspects. Often our expert engineers test this product widely and after the validation of checking it is finely delivered to the customer respectively.

The parts of the heat exchanger tube include the most important components of products… front and rear headers, the front and rear headers of heat exchangers where the liquids enters and leaves the tube, transfer line exchangers, air cooling system, and much more other parts are elaborately described in the product sections.

Usually the best material for heat exchanger is an aluminum and copper. Both the metals have the optimal properties and corrosion resistance in making ideal choices with most of the application specific requirements. In order to grown up your business of heat exchangers, shell tube exchangers, hydraulic oil coolers, fin fan coolers, turbine oil coolers, and much more other products of heat exchangers, our Pioneer Heat Exchangers Manufacturers perform their superior way of delivering the products to the required customers.